1. INTRODUCTION

1. INTRODUCTION

Under duplicated loading from traffic the track progressively moves, causing deviations through the desired straight and horizontal positioning. Ballast tamping is the process to bring back the geometry and re-arrange the ballast under the sleeper to help keep the track in position and provide it with a homogenous ballast bed. The track geometry must be calculated frequently or at least, the track is tamped at regular intervals to ensure that trains can travel properly on typical speed regarding the line.

When using substandard machines or any other handbook tamping practices, geometry is fixed using track jacks together with aesthetic judgement associated with Track Master. These processes aren't able to supply the quality or durability required for a contemporary railroad range. On any modern-day railway today, tamping devices with automatic lifting, coating and synchronised tamping on available track, turnouts, examined rail sections, splice bones etc. is really important for keeping the track on needed criteria.

On any modern-day railway today, tamping devices with automatic lifting, coating and synchronised tamping on available track, turnouts, examined rail sections, splice bones etc. is really important for keeping the track on needed criteria.

Choosing the right machine for particular track about traffic, size, axle running, wide range of turnouts, checked railway areas, spice joints, restricted track etc, is very a technology. To do this one needs to possess a good understanding of the machine types available, their particular elements and procedures to select the most affordable solution.

2. FUNDAMENTAL TAMPING PROCESS

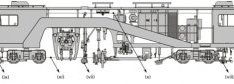

The most important working aspects of a tamping device are shown in Figure 1.

1 – Back Measuring Trolley 5 – Centre Measuring Trolley

1 – Back Measuring Trolley 5 – Centre Measuring Trolley

2 – Satellite (Continuous Action) 6 – Lifting and coating product

3 – Tamping Device Frame 7 – Front Measuring Trolley

4 – Tamping Unit/s

Figure 1: Operating Aspects Of Tamping Device

(09-3X Continuous Action Tamping Device Illustrated)

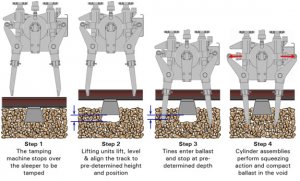

Figure 2 provides a schematic illustration associated with tamping procedure in 4 simplified actions.

Step 1 – a fundamental tamping device indexes ahead and involves a standstill with all the tamping tines for the tamping unit straddling the sleeper is tamped on both edges.