How-to produce Oxidized Bitumen? Production process:

- Bitumen heating to 265-270 °C

- Moving melted bitumen to blowing towers

- Blowing air to bitumen

- Cooling melted bitumen with liquid

- Packing.

The treatments of making bitumen

tend to be as follows:

- Constant blowing process

- Discontinuous blowing process

Both of these procedures are done-by various other two processes known as catalysis and anticatalysis. Catalysis implies incorporating some chemical material throughout the process In order to reduce blowing response time.

These are advantages of the discontinuous producing procedure:

- Ease and ease in altering blowing problem but manufacturing with different grades as a result.

- Ease in producing the system.

- Ease in technology and low expense in investment.

Technical point and operating conditions are as follows:

- The blowing should be done from the base of blowing tanker. The response between bitumen and atmosphere is calorific. If temperature created throughout the combination is large, the warmth of response is managed by-water injection.

- Admixture of air and also the number of blowing atmosphere are two crucial alternatives in blowing process.

In bitumen producing plant, bitumen 60/70 is generally got by blowing. In this situation in making bitumen 90/15 or 85/25 distilled made use of oil or crude oil ought to be injected to your item in line with the amount 20-25 per cent usually the fragility in bitumen lead to substandard manufacturing.

In bitumen producing plant, bitumen 60/70 is generally got by blowing. In this situation in making bitumen 90/15 or 85/25 distilled made use of oil or crude oil ought to be injected to your item in line with the amount 20-25 per cent usually the fragility in bitumen lead to substandard manufacturing. - Enhancing the heating heat, air injection quantity, some time tower pressure raise the speed of production process response. The best temperature for production operation is 265-270 °C which will be managed not to be ascended since in temperature as well as in 288 °C strength of effect becomes more sever and incontrollable which induce surge in tower.

- The long-time stay of bitumen in tower in almost any problem is not in favor of system and may be brought to drum or empty tanker after being ready.

- If fluid area in blowing tower is reduced, not more than specific limit should be included with the system for the additional atmosphere gather in bare components and result in ignition nearly. Incase the heat is held large, the within heat of tower ascend fats and this problem cause inside surge and harm the device.

- Blowing tower is chock-full to 70percent. Air injection is completed in 190-232°C. The final point of blowing is specified by sampling and testing of bitumen properties. Eventually the temperature of item should really be held 150- 165 °C so that you can have loading and packing capacity.

Manufacturing process can be uses:

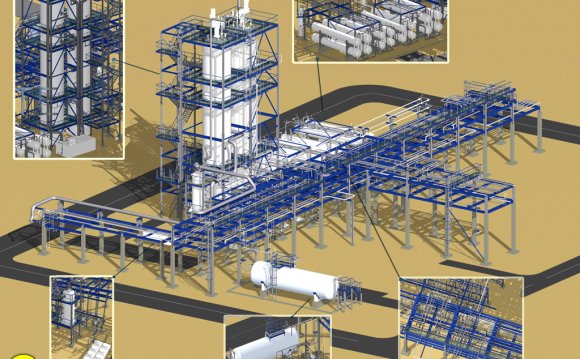

The making operation of oxidized bitumen mainly includes container running various actions, bitumen blowing, condenser external fumes and packaging. Therefore at first the loose bitumen delivered to your plant by tanker is utilized in the natural product shop tanker. In order to transfer the bitumen quickly toward blowing tower the burner is contrived in the bottom regarding the store tanker to heat them. It is important to say when the blowing towers tend to be bare, hot bitumen can be uploaded straight to them and blowing procedure begin.