Only 20% of Alberta's bitumen reserves tend to be near enough to the outer lining is mined. The remaining can only just be feasibly extracted in-situ (or perhaps in spot) using vapor. Although in-situ bitumen removal usually had low data recovery rates, current developments in technology have allowed for considerable process improvements. Smaller handling plants and higher production prices have significantly improved the profitability of in-situ extraction, that has become a growing number of popular within the oil sands and wants to guide the development in bitumen manufacturing through after that few years.

In-situ facilities contain here standard unit businesses:

- some well shields spread for the oil sands deposit

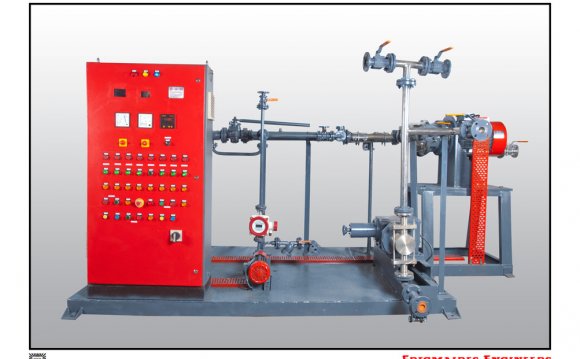

- a steam and energy generation plant which supplies power for facility and high-pressure steam for shot to the wellheads

- a central processing plant where oil and water emulsion produced on injection wells is divided

- a liquid therapy plant where in actuality the recovered liquid is cleaned and recycled back into the procedure, and

- an item storage space facility in which the bitumen is diluted with condensate for storage and transportation via pipeline.

An in-situ handling plant is usually a lot smaller and less complicated than an oil sands mining center. But bitumen can simply be extracted in-situ if oil sands deposit is deep underneath the area. Many in-situ deposits lie about 200 meters below quality.