Above 94 per cent of this nation’s two million kilometers of roads and highways tend to be paved with asphalt. That’s because condition and national highway departments have long understood that asphalt sidewalks are smooth, economical to make and continue maintaining, remarkably durable, green, and completely recyclable.

Really, the asphalt pavement industry generally speaks of asphalt facilities, maybe not asphalt plants-because these are mixing facilities. All over country, asphalt facilities are put alongside homes, companies, tennis programs, and facilities. Odds are good there is an asphalt facility maybe not definately not you for years, while didn’t even understand it was truth be told there.

In addition, you may be thinking we’re nitpicking, but asphalt “plant” (more popular term) is misleading for the reason that it indicates the production of petroleum asphalt it self, which suggests an oil refinery.

What exactly precisely is asphalt?

Just what people suggest when they state “asphalt” – also referred to as blacktop, macadam, or tarmac – is really a particular product, known within our business as asphalt pavement, or occasionally, Hot Mix Asphalt (HMA) pavement.

There's two standard ingredients in hot-mix Asphalt. The first is aggregates (broken rock, gravel, and sand). The aggregates made use of are nearly always locally readily available stone. About 95 % for the complete fat of an asphalt pavement consists of aggregates.

The remaining five % is Asphalt Cement, the black liquid that acts as the glue to keep the pavement collectively.

Asphalt Cement (AC) is a petroleum product generally obtained through the exact same refineries that create gasoline for your automobile and heating oil for your house. Asphalt Cement is amongst the heaviest, most viscous parts of petroleum. Combine the two ingredients together, while get hot-mix Asphalt.

Therefore, that’s all that happens at an asphalt facility?

Basically, yes. The paving aggregates are dried and heated, after that blended and coated with Asphalt Cement. The hot-mix Asphalt is invest silos for short-term storage, then trucked to the paving web site.

Why do we are in need of an asphalt facility during my neighborhood?

Hot-mix Asphalt is generally combined at conditions between 300 and 325 degrees-cooler than just what you’d used to bake a cake. And contains become set hot, no less than about 250 degrees. Getting HMA from center on paving site is like delivering a pizza. The farther you must make it, the cooler it gets. If it gets also cool, its no further ideal for paving.

Health danger problems?

If you see an HMA center, you’ll note that the people working there wear typical construction garments like difficult hats, gloves, and long-sleeved shirts. The best danger is from getting burned. Everything you won’t see is anybody wearing a respirator. There's absolutely no research the low degrees of emissions from an HMA center pose health threats to people.

But don’t you have to hold dangerous chemical compounds on location?

Liquids that needs to be managed carefully at a Hot Mix Asphalt facility are: 1) gas oil for burner, which is the exact same variety of fuel oil you may be utilizing to warm your property; 2) gasoline for automobiles, which is the exact same item you buy during the gas place; and 3) at some services, solvents for the quality-control lab. These solvents are used in tiny amounts with great care, and brand-new laboratory treatments tend to be quickly making solvents obsolete.

By federal legislation, a hot-mix Asphalt center must hold these items, including the gas oil, either in underground tanks that meet rigid EPA standards, or in above-ground tanks in the middle of berms that will hold ALL the articles in case of a spill.

What goes on when there is a spill or drip?

Asphalt Cement starts to solidify as soon as it cools. Unless it is 250 degrees Fahrenheit outside, it just cannot travel throughout the floor lots of legs. It does not penetrate the soil more than an inch or two before solidifying. Asphalt Cement does not blend with, or come to be dissolvable, in water.

What about the surroundings?

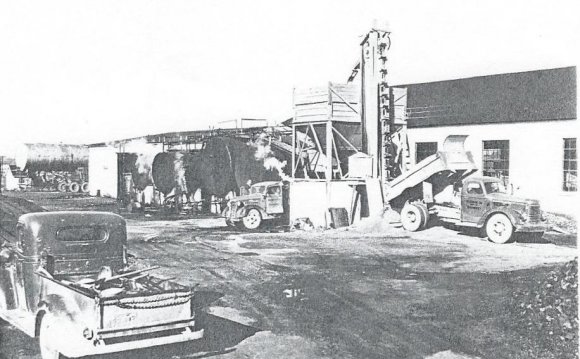

Above 30 years ago, hot-mix Asphalt facilities usually generated noticeable quantities of dust, smoke, smells, and sound. But a few things have brought huge modifications. One was the EPA’s brand new Source Performance guidelines, which went into impact in 1973. These needed HMA manufacturers to pass strict emission requirements and install control systems to prevent the production of dirt and smoke into the atmosphere. A facility must fulfill stringent “visible emissions” examinations so that you can adhere to laws. EPA today acknowledges that HMA services are not a significant way to obtain emissions.

An even more powerful incentive for clean operation is economic. it is inside owner’s best interest to make sure that all of the equipment is operating at top efficiency – which means making little in the form of emissions.

Hot-mix Asphalt producers wish to be great neighbors. They attempt to develop clean, peaceful services compatible with other community.

When people have the facts about contemporary HMA services, they understand the importance of having one in their neighborhood. Plus they appreciate their critical part in building and maintaining the nation’s infrastructure.