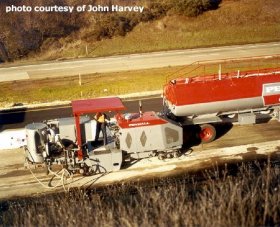

Diamond grinding (Figure 1) refers to an activity where gang-mounted diamond saw blades (numbers 2 and 3) are accustomed to shave off a thin, 1.5 – 19 mm (0.06 – 0.75 inch) top level of an existing PCC area to be able to restore smoothness and friction faculties. Oftentimes, it's accustomed restore roadway rubbing or pull roughness caused by faulting, studded tire use, and slab warping and curling.

Diamond grinding (Figure 1) refers to an activity where gang-mounted diamond saw blades (numbers 2 and 3) are accustomed to shave off a thin, 1.5 – 19 mm (0.06 – 0.75 inch) top level of an existing PCC area to be able to restore smoothness and friction faculties. Oftentimes, it's accustomed restore roadway rubbing or pull roughness caused by faulting, studded tire use, and slab warping and curling.

Purpose

Corrective upkeep. Restores pavement smoothness and frictional faculties. Could also be used in brand new construction to realize initial specified smoothness, although correctly built PCC pavements must not need any diamond grinding.

Corrective upkeep. Restores pavement smoothness and frictional faculties. Could also be used in brand new construction to realize initial specified smoothness, although correctly built PCC pavements must not need any diamond grinding.

Products

Gang-mounted diamond saw blades.

Other Information

Diamond grinding details serviceability issues not their particular cause. As an example, diamond milling can substantially decrease the roughness on a faulted rigid pavement, but it won't address the explanation for faulting, nor can it avoid roughness as time goes on because of additional faulting.

Considering that the milling mind is cooled with water, a byproduct of diamond grinding is a slurry of surface PCC particles and water. Nearly all of this slurry is acquired by vacuums inside the milling machine and either deposited over the highway shoulder (in some outlying areas) or collected in vehicles for disposal.