Clay paving stone is different from brick utilized on residence wall space. Paving bricks are solid, without holes and fired to a new standard than face brick to ensure lasting durability: ASTM C902 (pedestrian & light traffic) or ASTM C1272 (heavy vehicular). All Pine Hall Brick pavers exceed the absolute most strict ASTM standards.

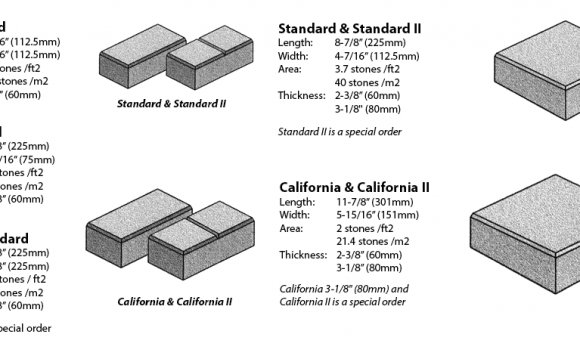

Sizes

- BONDED or LTW (length = twice width) 4"x 8" – Sand Joint Solutions

- MODULAR (7 5/8"x 3 5/8") – Mortar Joint Applications (concrete base)

Sand Joint Applications (sand setting sleep or bituminous setting bed):

- three paver thicknesses: 1 3/8", 2 1/4" (typical), 2 3/4"

- paver depth considering traffic loading or height demands

- reduced set up prices

- pavers can be un-zipped and re-laid (sand bed applications); lower upkeep prices

- doesn't require a stone mason for set up

- top kind of application-sand shared and establishing bed on crushed rock base

Mortar Joint Applications (mortar setting bed on concrete base):

- two thicknesses: 1 3/8", 2 1/4"

- unique look not the same as sand based; different colored mortars add wide selection of colors

- greater installation costs- work plus tangible base

- higher upkeep prices

- usually put in by stone masons

- Extruded: shale or clay is blended with water and pushed into vacuum pressure under high-pressure. Then, a column of “green” shale extrudes out the head of a brick device like enamel paste coming out of its pipe. The line is slashed by wires to make individual pavers. The pavers are dried out and fired to temperatures more than 2000 degrees. 90per cent of clay pavers are made from this method. All Pine Hall Brick pavers are extruded.

- Molded: clay is combined with liquid and forced into a mold manufactured from timber. Sand is usually familiar with line the mold so the green paver could be removed. Different colored sands offer different colors. The pavers are dried out and fired much like extruded pavers. Molded pavers tend to be popular simply because they stated in a means much like the stone making process made use of hundreds of years ago therefore, look antique.

- Dry Pressed: almost dried out clay is pressed into a metal mildew under ruthless. Vacuums enable you to extract air making the paver much more thick. With less moisture, dry pressed pavers will shrink less thus giving these items good dimensional security. The firing procedure is similar to compared to extruded and shaped pavers. The blending process is typically done in batches that enables for much easier blending of various clays to produce color types.

Source: www.pinehallbrick.com