- U.S. Division of Labor

- Occupational Protection and Wellness Administration

- Directorate of Technical Support and Emergency Management

- (previously Directorate of Science, Technology and drug)

- Office of Science and Tech Evaluation

Protection and Health Information Bulletin

This Safety and Health Suggestions Bulletin is certainly not a regular or legislation, plus it creates no brand-new appropriate obligations. The Bulletin is consultative in nature, informational in content, and is intended to help companies in offering a secure and healthy office. Pursuant towards the Occupational Safety and wellness Act, employers must comply with hazard-specific protection and wellness standards and regulations promulgated by OSHA or by a state with an OSHA-approved condition plan. Additionally, pursuant to Section 5(a)(1), the typical Duty Clause regarding the Act, employers must definitely provide their workers with a workplace free from acknowledged risks expected to trigger demise or really serious actual damage.

Preface

Between 2000 and 2006, OSHA investigated over 50 rollover incidents that involved many different roller/compactor makes and designs. Associated with rollover accidents investigated:

- 5 involved roller/compactors with rollover protective frameworks (ROPS) where operators utilized the seatbelts supplied. Nothing of the accidents led to a fatality.

- 19 involved roller/compactors with ROPS, but seatbelts were not made use of. In many cases, seatbelts were not provided. In other situations, the seatbelts provided are not employed by the operators. Fourteen of these accidents triggered fatalities. In many different these instances, the operator was either ejected or hopped from gear, and had been pinned under or crushed because of the ROPS.

- 1 case involved a pneumatic rubber-tired roller/compactor in which the ROPS and seatbelt was in fact eliminated ahead of the accident. The operator involved had been fatally hurt within the accident. This accident is described below (Accident # 1).

- 6 situations included pneumatic rubber-tired roller/compactors without ROPS. Throughout of the situations, the accident triggered a fatality. One such accident is explained below (crash number 2).

The deadly accidents within the last two bullets above would be the focus with this security and Health Ideas Bulletin (SHIB), and are usually described in detail below.

The deadly accidents within the last two bullets above would be the focus with this security and Health Ideas Bulletin (SHIB), and are usually described in detail below.

Purpose

The goal of this protection and Health Suggestions Bulletin is to:

- to tell businesses and workers associated with rollover danger whenever operating roller/compactor devices, and that ROPS and seatbelts decrease the chance;

- to alert users and operators that, when they run roller/compactors on uneven surfaces, the chances of a rollover is substantially increased; and

- to encourage businesses to very carefully assess roadways and work areas where roller/compactors tend to be run for dangerous inclines/declines.

Background

The OSHA Englewood Area workplace investigated two deadly accidents in 2005 in south Colorado relating to the rollover of pneumatic rubber-tired roller/compactors. The devices associated with these fatal accidents were made by different producers, nonetheless they had been much the same in the wild. Each machine had pneumatic rubberized tires and a minimal center of gravity. These devices tend to be found in the compacting procedure during road building and paving functions.

Both in situations, OSHA concluded that in the event that device was in fact built with a ROPS system, of course the operator was in fact putting on a seatbelt, the likelihood of the operator's survival could have more than doubled.

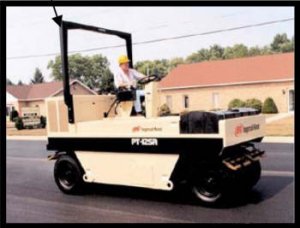

Roller/Compactor Taking Part In Accident number 1

(ROPS and seatbelts had been removed before the accident)

Pneumatic-tired Roller/Compactor

Figure 1

Roller/Compactor Associated With Accident #2

(ROPS was not supplied together with operator had not been using a seatbelt)

Self-Propelled Pneumatic Tired Roller/Compactor

Figure 2

Accident Description

- Crash #1 - In May 2005, a member of staff had been fatally injured while running a pneumatic rubber- exhausted roller/compactor on a roadway during asphalt compacting. The roller/compactor went off the road and traveled down a 22-degree sloping embankment. It rolled over 1½ times, coming to a stop on its top. The operator had been thrown through the device and ended up being fatally crushed between the machine and the floor. Even though roller/compactor had been initially equipped and offered with a ROPS and a seatbelt, the ROPS and seatbelt was in fact eliminated prior to the accident.

- Accident #2 - In August 2005, an employee ended up being running a pneumatic rubber-tired roller/compactor on a gravel roadway, rolling magnesium chloride into the gravel. The roller/compactor ran from the roadway and traveled down a 28-degree sloping embankment. It rolled onto its part and came to an end. Whilst the device traveled along the embankment, the operator ended up being tossed from the device and fatally crushed. The roller/compactor had not been provided with a ROPS and also the operator wasn't using a seatbelt.