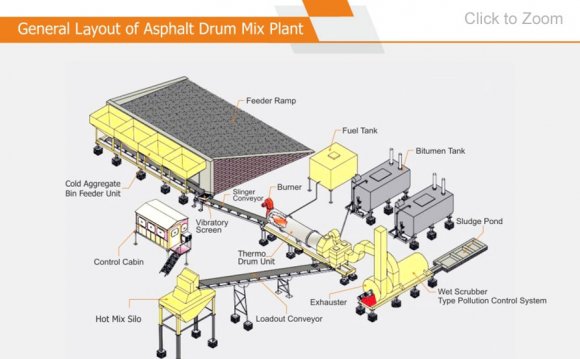

4-Bin Feeder

It really is of solitary framework construction. At each Bin a radial gate is offered which may be established in virtually any place to manage the aggregate circulation. Individual endless belts are offered below the gates to discharge product on the gathering buckle.

Vibrating Screen

A single-deck vibrating screen is offered regarding slinger conveyor to get rid of oversize aggregate obtained from the 4-bin feeder.

Slinger Conveyor

An inclined conveyor attached to idlers obtains aggregate from the gathering conveyor and feeds it into dryer.

Dryer Drum

The dryer is accurately fabricated to make certain appropriate heating of aggregates with minimal temperature loss. Specifically designed routes raise and cascade the aggregate to cut back the last moisture content to 0.5% (by fat). It really is supported on metal rollers through metal tyres with idlers and guide rollers and it is supplied with segmented operating sprocket. A completely automatic high-pressure automobile jet burner is mounted at one end of the drum. The discharge chute design discharges heated aggregate directly on the loadout conveyor.

Bitumen Tanks

One/Two Bitumen Tanks of 15/20 MT. capacity each are provided, fabricated from steel plates with 50 mm glasswool insulation, manhole, thermocouples, etc. Bitumen is moved towards the dryer drum through pipeline lines. Tanks are fitted with independent on-off kind burners.

Multicyclone Exhaust

The dust collection system is comprised of encased numerous cyclones, exhaust lover and chimney.

Burden Out Conveyor

Blended aggregate through the dryer drum is released on a willing conveyor supplied with a hydraulic hopper at delivery end for feeding the Combine into Tippers.

Mineral Filler

Fabricated from metallic dishes, it nourishes the mandatory quantity of mineral toward drum.

Control Cabin

A totally automatic control interface with feather touch controls is given to controlling the amount and top-notch manufacturing with operator sitting in Air-conditioned comfort.

All methods are completely synchronized with automated / handbook control over burners, load cells, mix heat, cold feed / mineral / bitumen proportions, etc. Manual control is possible through over-ride system. Sufficient safety precautions are adopted in order to prevent overloading, short-circuit, etc.