Background

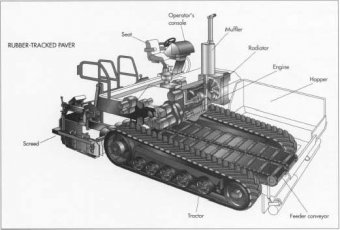

An asphalt paver is a device accustomed circulate, shape, and partially compact a level of asphalt on top of a roadway, parking lot, or other area. It really is occasionally called an asphalt-paving device. Some pavers tend to be towed by the dump truck delivering the asphalt, but most are self-propelled. Self-propelled pavers contains two major elements: the tractor plus the screed. The tractor provides the forward motion and distributes the asphalt. The tractor includes the engine, hydraulic drives and controls, drive wheels or paths, getting hopper, feeder conveyors, and circulation augers. The screed amounts and forms the layer of asphalt. The screed is towed by the tractor and includes the leveling hands, moldboard, end plates, burners, vibrators, and pitch sensors and controls.

Functioning, a dump truck filled up with asphalt backs around the leading of the paver and gradually discharges its load into the paver's hopper. As paver moves ahead, the feeder conveyors move the asphalt into the back associated with the paver, and circulation augers press the asphalt outward to the desired width. The screed after that levels the layer of asphalt and partially compacts it on desired form. Huge, steel-wheeled roller uses the paver to help expand compact the asphalt to the desired thickness.

History

Asphalt as a paving product dates back to 1815, when Scottish roadway professional John McAdam (or MacAdam) developed a roadway surface composed of a compacted layer of little stones and sand dispersed with liquid. The water dissolved the natural salts regarding the stones and aided cement materials collectively. This kind of roadway area was known as liquid macadam in his honor. Later, coal-tar was made use of as a binding product as opposed to liquid, together with brand-new pavement became generally tar macadam, where we get the shortened term tarmac that is occasionally used to describe asphalt pavement.

Tar macadam pavement had been used in the United States up through start of the twentieth century. Modern blended asphalt pavement, which provides a far more durable road surface, ended up being introduced in the 1920s. Unlike macadam, when the rock and sand aggregates tend to be laid on the highway area before being dispersed because of the binding material, the aggregates in combined asphalt are covered using binding product before they've been set. Initially, mixed asphalt ended up being just dumped on roadway and raked or graded degree before becoming rolled smooth. In 1931 Harry Barber, of Barber-Greene business, developed initial mechanical asphalt paver in america. It traveled on a set of steel rails and included a combination loader and mixer to proportion and blend the elements before distributing the asphalt uniformly on the road surface. The rails were shortly changed by crawler tracks, and also the first production paver emerged from the Barber-Greene range in 1934. This new machine quickly became popular with roadway builders since it allowed them to position asphalt faster in accordance with greater uniformity. Hydraulic drives replaced technical drives in pavers during late 1950s to give the operator also smoother control. Today, practically all asphalt is put making use of paving machines. Considering that 98percent associated with roadways in america tend to be asphalt, you are able to understand the worth of the asphalt paver.

Recycleables

Most of the components of an asphalt paver are made of steel. The tractor mainframe is fabricated from heavy-gauge metallic dish. The feeder conveyor is made of heavy-duty string with forged steel areas, called trip bars. The circulation augers are constructed with cast Ni-Hard steel. The screed is fabricated from steel tubing, channel, and plate. The motor address and access doors tend to be created from steel sheet.

Rubber-tired pavers have two huge expansive back drive tires and four or maybe more smaller solid rubber steering tires. Rubber-tracked pavers have actually a molded artificial rubber track with a number of interior layers of flexible steel cable for support. The track is driven by a friction drive wheel from the back, therefore the load is distributed among several intermediate rubber-coated steel bogie rims. A hydraulic cylinder presses against the forward wheel to keep tension in the track.

Purchased components on a paver range from the motor, radiator, hydraulic elements, batteries, electric wiring, devices, tyre, and operator's seat. Purchased fluids consist of hydraulic fluid, diesel gasoline, engine oil, and antifreeze.

Design

Many producers of asphalt pavers provide a few sizes and models. Engine horse power is generally in 3-20 hp (2-15 kw) range for smaller, towed pavers, and may maintain the 100-250 hp (75-188 kw) range for larger, self-propelled pavers. Many engines utilize diesel gas because that is the gas widely used on various other construction equipment.

Most larger, self-propelled pavers are about 19-23 ft (5.8-7.0 m) very long, 10 ft (3.1 m) large, and 10 ft (3.1 m) high. They weigh about 20, 000-40, 000 pound (9, 090-18, 180 kg) with regards to the hopper ability, engine dimensions, and variety of drive system. The typical rate of asphalt placement is 100-300 ft/min (31-92 m/min). The typical paving width is 8-12 ft (2.4-3.7 m) up to a maximum width of 40 ft (12.2 m) by using screed extensions on some devices. The maximum paving depth about the same pass is 6-12 in (152-305 mm).

Options include burning plans, handbook and automatic screed extensions, and various sensors and controls to improve the class (fore-aft measurements) and slope (side-to-side measurements) of this level of asphalt.

The Manufacturing

Process

Asphalt pavers are put together from component parts. Many of these parts tend to be fabricated inside set up plant, while some are made elsewhere and tend to be transported towards the plant. All parts get a primer coat of paint. The parts are stored in a warehouse consequently they are delivered to numerous work programs or places as required.