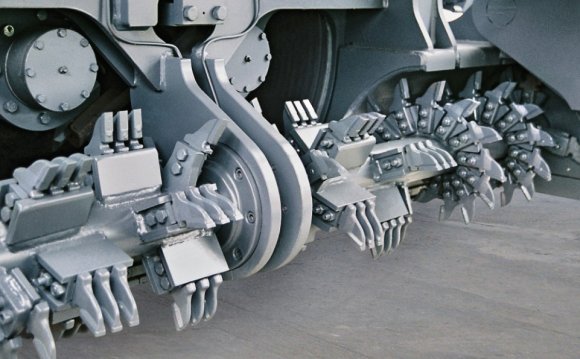

A. Yes. All jobs today use a Preheater prior to the Repaver. The preheating starts the softening for the present area to permit scarification regarding the specified level. In some cases, multiple preheater is essential to achieve the desired scarification depth.

A. The level may differ based upon the width of the final overlay, the penetration and viscosity of this asphalt concrete and kind of aggregate in the pavement surface. In general, a depth of just one inches can routinely be performed of all metropolitan asphalt areas.

Q. Can scarification depths greater than 1 inches be achieved?

A. Yes. However, each pavement must be assessed individually to ascertain whether the asphalt properties contained in the pavement enables a higher level. Typically, many urban pavements do not require depths higher than one inch. Some highway pavements may be suited for depths of 1-1/2 to 2 ins, but a thorough pavement analysis must be done in conjunction with an expense analysis to look for the feasibility of attaining a 2 inch depth.

Q. Exactly how much current asphalt must successfully recycle it because of the Cutler solitary machine process?

A. We recommend the current wearing surface consist of 1-1/2 to 2 ins of asphalt if a scarification depth of just one inches is desired. For just two inch level, we recommend a 4 inch total width.

A. Usually, the very least 1 inches of virgin hot-mix asphalt is added during recycling procedure, producing a combined 2 inches width of new and recycled hot-mix. On recycling depths more than an inch, it might be feasible to put surface programs significantly less than 1 inch thick."

Q. What's the optimum quantity of brand-new hot mix that can be added through the recycling procedure?

A. For recycling depths of 1 inch, a 2 inches overlay is maximum. Good principle could be the complete thickness of new and recycled material should not exceed 3 inches.

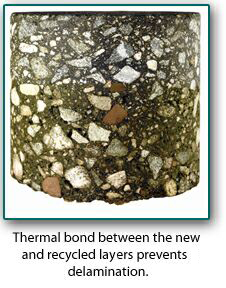

Q. Does the Cutler process prevent delamination amongst the recycled and brand-new hot-mix asphalt levels?

Q. Does the Cutler process prevent delamination amongst the recycled and brand-new hot-mix asphalt levels?

A. Our procedure produces a monolithic relationship between the two levels (see image). Our unique solitary device technology heats and reworks the prevailing surface, generating a recycled level this is certainly at the very least 200° F during the time this new overlay is used with the same machine.

Q. What life pattern can I anticipate from your own recycling procedure?

A. Under normal conditions, our recycling projects will deliver at least 7 to 12 (See Pavement Lifecycle Cost Per Year chart at bottom of Economic Benefits page). However, some Cutler projects have delivered as much as 19 years of service before subsequent resurfacing was required.

Q. Can the Cutler solitary machine recycling procedure be utilized along with SuperPave technology?

A. Yes. Cutler's hot in-place recycling process is an ideal means to fix remove rutting and area problems just before laying down new SuperPave surface course. Our procedure saves time, products, and cash with the use of the recycled product as a leveling course.